- #WOODPECKER 3.2 GRBL DOCUMENTATION MOD#

- #WOODPECKER 3.2 GRBL DOCUMENTATION DRIVERS#

- #WOODPECKER 3.2 GRBL DOCUMENTATION FULL#

- #WOODPECKER 3.2 GRBL DOCUMENTATION PROFESSIONAL#

This might be a bit small if you wanted to make a complete cover made out of this stuff Thanks for the shielding material tip, I may buy it later if starting to work with 0.5w 405nm laser for engraving. It is rated for the wavelength of my laser module which is 450nm. I got a piece of this to replace the plexiglass on the door of my enclosure. One of the tools is a 6 watt laser module.

#WOODPECKER 3.2 GRBL DOCUMENTATION MOD#

Not long ago I made a mod for my 3D printer that allows me to change to different tool heads. I made an enclosure for my 3D printer in which I had a plexiglass panel for the door.

#WOODPECKER 3.2 GRBL DOCUMENTATION FULL#

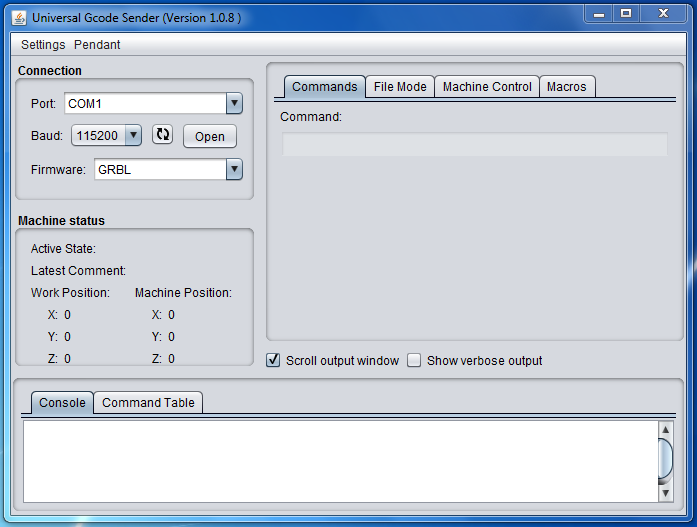

I have only found out so classes for protecting from the beam but would rather like to see a full box made from proper shielding material on top of the Eleksmaker.įourths interesting thing is the openpnp based pasta dispenser and pick and place machine. Laser is interesting due to it's accuracy but I am worried from the reflected beams. I'll be plugging them into a RAMPS board, which is cheap, and which, as an arduino Mega 2560 shield, will replace the woodpecker said in CNC PCB milling: I got a couple extra in case I accidentally burn one or two of them out.

#WOODPECKER 3.2 GRBL DOCUMENTATION DRIVERS#

The yet to be used trinamic drivers cost $42.50: Not sure yet whether the new spindle will eventually produce better results or not, although it does run quieter, which is nice. My feeling is that the steel rods are a worthwhile and very easy upgrade, even though I don't have data to prove they make any difference. The 6 chromed steel smooth rods cost around $20-30 in total, including e-packet delivery. Aside from the plastic filament needed for the print (maybe $2 worth), it requires just 4 short linear bearings and a lead nut. I had to 3D print an adapter for the new spindle to fit onto the 2418. I power it with a separate, adjustable power supply, since it can go to 48v. The spindle I'm currently using cost $34: What was the cost for the overall upgrade? Or, just get this, which goes to 24,000RPM and has water cooling already a part of said in CNC PCB milling:

The main downside to that is that it would require installing an ER11 collet, and so runout might be an issue. It could also go up to around 48,000RPM at 12v. Notionally, something like: Īlternately, I notice an inexpensive brushless motor with a water cooling jacket already installed, for not much money: Perhaps it would be possible to buy a water cooling jacket for the spindle? That would cover the bases against even heavy duty use. adapts to maintain the target RPM even under varying loads), then it would be very attractive. I have the same mill as you, and swapped for one of these and have had much better results so far.ĭoes the controller that comes with your motor allow you to set the RPM of the motor, or does it just set the voltage? If it knows RPM and can act like a PID (i.e. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it. You might be able to find other specs, but the ones I've found suggest that at 24V and no load, they claim 7kRPM - I'm not sure how much slower we could expect it to be while milling. Get a 3d printer, get a 3040/6040 cnc, get a 40/50W laser, get a lathe if you have space for it, maybe get a vertical mill for metal parts and you'll have a maker space of your own, as long as you won't start manufacturing space ships ebay tool tolerances will be said in CNC PCB - the motors used in 1610 CNC mills are generally what are called a "775 Motor".

#WOODPECKER 3.2 GRBL DOCUMENTATION PROFESSIONAL#

Too many times I've spent a fortune for professional tools which I don't use/need so I tend to get what I need + a small margin, for eg I got a huge DSLR and lenses, used a few times, great photos, but lately, guess what, I tend to use my phone for taking photos 99.9% of the time, the camera backpack is just too heavy to carry arround. I'm so happy with my $50 UT61E, what a great multimeter, of course I would rather have a HP 8.5 digit one any day but I'd rather spend that money on a holiday or something since I don't need that 0.0001uV precision anyway, at 1V a 3V bat is as empty as a 0.9999999987V one if you get my point. Professional machines do a better job at a higher price tag. Specialised machines do a s specific job better than general purpose ones, but only do that job. And finding a good tool at an affordable price is a challenge.

0 kommentar(er)

0 kommentar(er)